Design of Structural Steel Pipe Racks RICHARD M. The members used in chevron bracing are designed for both compression and tension Chevron bracings allows for doorways or corridors through the bracing lines in a structure.

Steel Frame Pipe Rack Tutorials Computers And Structures Inc Technical Knowledge Base

These clearances shall be as per Piping Design Basis.

. Heat pipes are connected to water loops to take away the heat. For pipe 12 minimum of 05 kNsqm As per design basis Pipe test load Test weight of the pipe 12 by piping. It connects all equipment with lines that cannot run through adjacent areas.

Pipe racks are structures in petrochemical chemical and power plants that are designed to support pipes power cables and instrument cable. If the support beam was concrete the thermal load was dead load factored wind was live. This type of solution needs DIMM pitch 035 037 as best case.

This solution works for the tighter DIMM pitch design. During design of Pipe Rack certain points need to be taken into consideration for optimal design. Best Practices for Design and Assembly.

Can also be considered based on area available. Flattened liquid pipe is implemented on the cold plate. For pipe 12 minimum of 12 kNsqm As per design basis Pipe operating load Operating weight of the pipe 12 by piping.

Piperack PR-06A is 1138m in lengthwise Fire proofing is considered upto 90m for design as per Industries standards and AISC 2nd Edition. Because it is located in the middle of the most plants the pipe rack must be erected first before it becomes obstructed by rows of equipment. PIPERACK DESIGN CONCEPTS PIPERACK LOADING Pipe Vertical Load.

Pipe racks are non-building structures that have similarities to structural steel buildings. Here are sample requirements for pipe rack design. A Pipe rack is a structure designed and installed specifically to support multiple pipes where an adequate building or structure is not available mainly outside the building.

Written by Anup Kumar Dey in Piping Design Basics. We used 10 of total pipe load as a lateral. It connects all equipment with lines that cannot run through adjacent areas.

Modular Designed Boiler Feed Water Pumps and Piping. In general equipment layout shall be prepared considering straight pipe rack however other shapes like L T U H Z etc. This checklist can be used at design stage as well as during 3D Model Review.

Pipe racks carry process utility piping and also include instrument and electrical cable trays as well as. Basically Overhead piping supported on steel or concrete bents. DRAKE and ROBERT J.

Pipe racks are structures in petrochemical chemical and power plants that are designed to support pipes power cables and instrument cable trays. Bolted structures allow pipe racks to be built in layers reducing assembly time. They may also be used to support mechanical equipment vessels and valve access platforms.

Bolted galvanized structural steel. Pipe rack is modeled in STAAD PRO software and all reactions forces and utility ratios are used for describing thesis thesis report. Some of these points are covered in following pipe rack design checklist.

WALTER ABSTRACT Pipe racks are structures in petrochemical chemical and power plants that are designed to support pipes power cables and instrument cable trays. Bracing connection may require large gusset plate at the beam to column joint. Pipe Racks PipeWay Arrangement Design.

Connection for X- bracing are located at beam to column joint. Industrial Plant Pipe Rack Foundations Analysis and Design Industrial pipe racks typically support pipes power cables and instrument cable trays in petrochemical chemical paper mills and power plants. Up to 10 cash back Description.

Updates 1 submitted by Manas Jyoti on Mon 11032008 - 0315. For offplot pipe racks longitudinal beam struts shall be designed for vertical and horizontal loads imposed by expansion loops located by piping group. Engineering design completed for pre-assemblies prior to field start.

Advanced procurement of long lead equipment and materials. A pipe rack is the main artery of a processing unit. Wini Sapong Created Date.

Pipe racks are necessary for arranging the process and utility pipelines throughout the plant. All piperack longitudinal beam struts shall be designed for a compression load of 15 of the maximum adjacent column load at beam level. Because it is located in the middle of most plants the pipe rack must be erected first before it becomes obstructed by rows of equipment.

Pipe empty load Dead weight of the pipe 12 by piping. Modular Designed Pipe Rack. Introduction Pipe-Rack Considered as Main Artery of a process plant.

Pipe thermal load is parallel with pipe axis. There are three types of pipe rack1 Conventional pipe rack 2 Non Conventional pipe rack 3 Modular pipe rack This is essentially a system where multiple 2-dimensional 2D frame assemblies comprised of two or more columns with transverse beams are tied together in the longitudinal direction utilizing beam struts and vertical bracing to form a 3D space frame. Located in the central part with branches to the sides.

A pipe rack is the main artery of a process unit. Occasionally pipe racks may also support mechanical equipment vessels and valve access platforms. Generally speaking what we didnt do was take wind blowing in a parallel direction with pipe axes inside the rack so the wind and thermal load seldom added together in a long pipe rack design.

Main pipe racks generally transfer process material between equipment and. Sir i m freshers as a design engineer and i need to do crude oil storage tankplease guide me how to design a tank farm foundation please provide detail of it with example. How to design a pipe rack and what are the load its into picture.

Flattened heat pipe is attached to memory case with TIM in the middle. The total width of pipe rack shall include 25 extra space for future expansion modifications in unit. They may also be used to support mechanical equipment vessels and valve access platforms.

And resolution of design related issues Purchasers Management representation to be assigned to. TraysThe design requirements found in the US building codes are not clear on how they have to be applied to pipe racksThis course summarizes the US design code requirements and industry practice.

Steel Frame Pipe Rack Tutorials Computers And Structures Inc Technical Knowledge Base

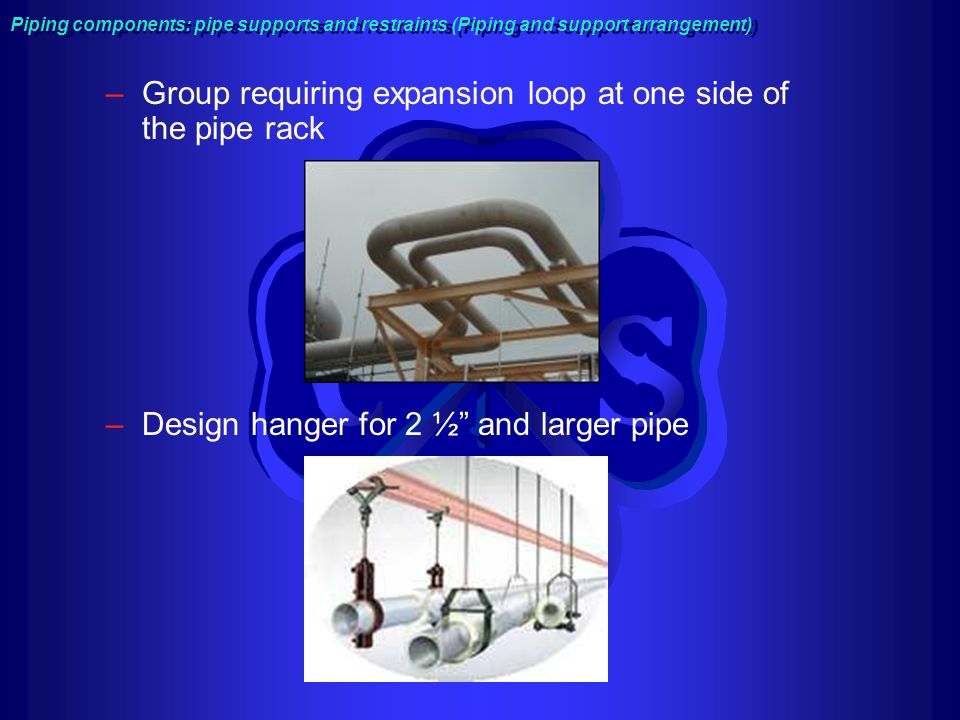

Pipe Supports And Restraints Ppt Video Online Download

0 comments

Post a Comment